The Concrete Insight team uses concrete petrography and other analytical methods to investigate concrete and other cement-based construction materials, natural rock products, and geological resources. With straightforward thinking, meticulous detail, and impeccable customer service, we provide our clients the information they need to understand the performance of construction materials.

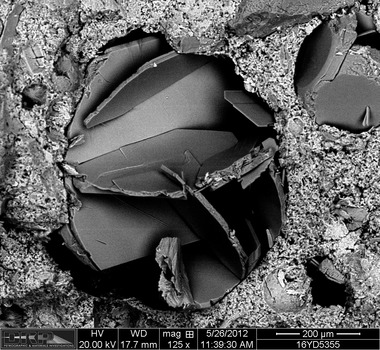

Petrographic examination is useful for identifying aggregates that are susceptible to alkali-aggregate reactions, lack freeze-thaw durability, are soft or incompetent, have deleterious coatings or excessive fines, and more. DRP has extensive experience with aggregate QA/QC for use in concrete or other cement-based materials following procedures described in ASTM C295, Guide for Petrographic Examination of Aggregates for Concrete. We have done petrographic examination on aggregates from all over North America, Central and South America, Asia, and scattered Pacific Islands.

Our team of experts are available to provide a wide range of solutions your concrete projects from providing quality assurance to diagnosing causes of deterioration. With extensive experience in concrete materials and early age problems, durability mechanisms, and the performance of slabs ranging from pavements to industrial floors, we help engineers formulate solutions that range from minor repairs to removal and replacement. We can provide:

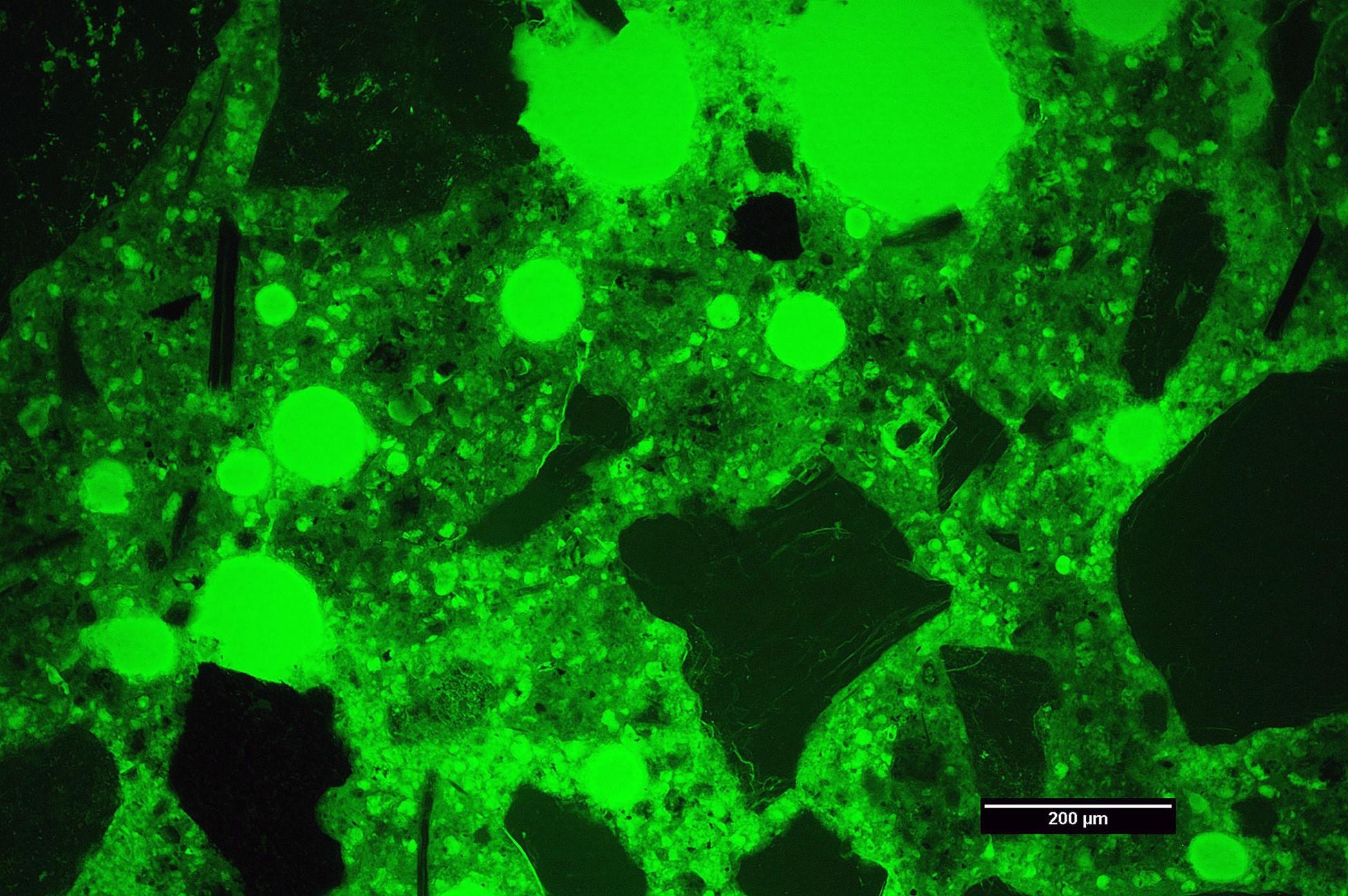

We routinely perform petrographic analyses on aggregates and microscopical air void analyses to help provide quality assurance of ready-mixed and precast concrete elements. We have extensive experience in troubleshooting early-age issues such as unusual setting behavior, curing issues, low strength and cracking.

- Concrete Aggregates

- Air Void Analysis

- Early Age Cracking

- Strength

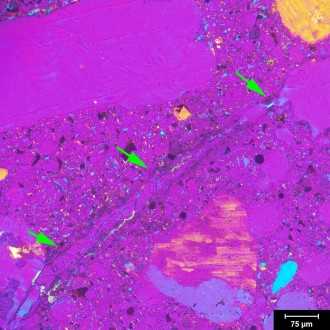

Our team is available to sort out complex problems regarding durability issues that include alkali-aggregate reaction, sulfate attack, salt weathering, freeze-thaw damage and scaling, chemical attack, corrosion and more.

- Alkali-Aggregate Reaction

- Sulfate Attack

- Salt Weathering

- Scaling

- Freeze-Thaw Damage

- Chemical Attack

- Carbonation and Corrosion

You can rely on our team’s experience in working with slabs and pavements that show excessive cracking, delamination, blisters, low wear resistance and other surface defects. We are also seasoned investigators of moisture migration issues and floor covering failures.

- Surface Defects

- Floor Coverings